Setting the Standard: Why Waveguides Demand Meticulous Engineering

A waveguide is more than a simple metal tube; it is a meticulously engineered structure designed to guide high-frequency signals with unparalleled efficiency. The internal geometry, material composition, and surface finish of every component directly impact performance. Even microscopic imperfections can cause signal reflections, power loss, and distortion, degrading the entire system. Meticulous engineering ensures that every part of a waveguide assembly works in concert to maintain signal purity from source to destination.

Defining “Peak Performance” in Custom Waveguide Assemblies

Peak performance in a waveguide assembly is the optimal balance of several key metrics. It means achieving the lowest possible insertion loss to preserve signal strength and the lowest Voltage Standing Wave Ratio (VSWR) to minimize signal reflection. It also means maximizing power handling capacity and ensuring consistent, reliable operation across a specified frequency range, even in extreme temperatures, pressures, or high-vibration environments. True peak performance is achieved when a custom assembly is perfectly harmonized with the system it serves.

Waveguide Fundamentals: The Backbone of RF Communication

Understanding the principles of waveguide technology is essential to appreciating the need for custom solutions. These components are the workhorses of RF and microwave communication, offering low-loss transmission that coaxial cables cannot match at higher frequencies.

What are Waveguides and How Do They Work?

A waveguide is a hollow, conductive metal pipe used to carry high-frequency radio waves. Unlike a traditional cable that transmits a current, a waveguide confines and directs electromagnetic fields within its structure. The wave propagates down the length of the guide by reflecting off its interior walls. This method of transmission is highly efficient, making waveguides the preferred choice for high-power applications and systems operating in the microwave and millimeter-wave spectrum.

Types and Dimensions: Rectangular vs. Circular Waveguide, WR Series (e.g., WR3 to WR650)

Waveguides come in various cross-sectional shapes, most commonly rectangular and circular. Rectangular waveguides are prevalent due to their well-defined polarization and broader single-mode bandwidth. The dimensions of a waveguide are critically important as they dictate the frequency range it can support. The industry standard “WR” designation (Waveguide, Rectangular) followed by a number, such as WR650 or the very large WR2300, indicates the width of the guide’s broad wall in hundredths of an inch. Each waveguide size is optimized for a specific frequency band, from lower frequencies up to extremely high ranges requiring parts like a WR-03.

Key Performance Indicators: Minimizing VSWR and Insertion Loss for Optimal Signal Integrity

Two of the most critical performance metrics for any waveguide assembly are VSWR and insertion loss.

- VSWR (Voltage Standing Wave Ratio): This measures the amount of signal reflected back toward the source. A low VSWR (ideally close to 1:1) indicates an efficient power transfer and minimal signal distortion.

- Insertion Loss: This quantifies the reduction in signal strength (attenuation) as it passes through the waveguide components. Lower insertion loss is crucial for maintaining the power and clarity of the communication signal.

The Imperative for Customization: Beyond Off-the-Shelf Solutions

While standard parts have their place, complex systems in aerospace, defense, and scientific research demand solutions tailored to unique operational parameters.

Tailoring to Unique Application Requirements and Customer Specifications

Custom waveguide assemblies are designed from the ground up to meet specific customer requirements. This includes non-standard frequency ranges, unique flange configurations, specific power handling capabilities, and integration with existing system architecture. By tailoring every aspect of the assembly, we ensure it performs not just adequately, but optimally within its intended application.

Overcoming Spatial and Environmental Constraints (e.g., Indoor, Outdoor, Vacuum Compatibility)

Modern systems often have tight spatial footprints and must operate in harsh environments. Custom manufacturing allows for the creation of complex geometries with precise bends and twists to navigate crowded layouts. Furthermore, material selection and fabrication techniques can be optimized for outdoor use, extreme temperatures, or the vacuum of space, ensuring long-term reliability where standard components would fail.

Optimizing Performance for Specific Frequencies and Power Levels (e.g., High Power Satcom, 220 GHz, 330 GHz)

High-power satellite communication or high-frequency research applications (e.g., 220 GHz or 330 GHz) push the limits of waveguide technology. Customization enables the design of parts optimized for a specific frequency, maximizing efficiency and minimizing loss. For high-power scenarios, features like heavy-wall construction, specialized materials, and enhanced cooling can be incorporated to manage thermal loads and prevent electrical breakdown.

From Prototype to Production: Scaling Custom Work

Our capabilities extend from creating one-off prototypes for research and development to full-scale production runs for system deployment. This seamless scalability ensures that the precision and performance validated in the prototype phase are consistently replicated in every assembly manufactured, maintaining quality and reliability regardless of volume.

Precision Engineering: The Foundation of Peak Performance

Achieving superior performance is a direct result of a rigorous, detail-oriented engineering and manufacturing process.

The Science of Material Selection: Balancing Performance and Application

The choice of material is foundational. Copper offers excellent electrical conductivity, minimizing signal loss, while Aluminum provides a lightweight alternative crucial for aerospace and space-flight applications. We also work with specialized alloys and plating options (like silver or gold) to enhance performance for specific environmental conditions or frequency requirements, balancing conductivity, weight, strength, and cost.

Advanced Design and Electromagnetic Simulation

Before any metal is cut, our custom waveguide assemblies are meticulously designed and validated using advanced computer-aided design (CAD) and electromagnetic (EM) simulation software. This virtual prototyping allows us to model signal behavior, predict performance, and optimize the design to meet or exceed all specifications for VSWR, insertion loss, and power handling before manufacturing begins.

State-of-the-Art Manufacturing: Achieving Micro-Tolerances

Translating a validated design into a physical assembly requires exceptional manufacturing precision. Our state-of-the-art CNC machining, dip-brazing, and assembly processes allow us to achieve micro-tolerances. This precision is critical; even minute deviations in dimensions can significantly impact performance at high frequencies. Every component is crafted to ensure a perfect fit and flawless signal transmission.

Rigorous Quality Assurance and Testing Protocols

Quality is verified, not assumed. Every waveguide assembly undergoes a battery of tests to confirm its performance against the design specifications. Using network analyzers and other advanced test equipment, we measure key parameters like VSWR and insertion loss across the entire operational frequency band. This rigorous testing guarantees that every product we deliver meets the highest standards of quality and reliability.

Comprehensive Range of Custom Waveguide Components and Assemblies

We design and manufacture a complete portfolio of waveguide products, enabling the creation of fully integrated, end-to-end custom assemblies.

Core Elements: Raw Waveguide and Custom Length Straight Sections

The foundation of any assembly is the straight waveguide section. We provide raw waveguide and precision-cut straight sections in custom lengths for all standard and non-standard waveguide sizes, ensuring a perfect fit within your system architecture.

Seamless Connections: Waveguide Flanges and Precision Transitions

Proper connections are vital for maintaining signal integrity. We manufacture a wide array of standard and custom flanges for seamless integration. Our precision transitions allow for low-loss connections between different waveguide sizes or between a waveguide and a coaxial connector, ensuring efficient signal flow across system interfaces.

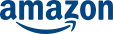

Navigating Complex Pathways: Miters, Bends, and Twists

To route signals through complex system layouts, we engineer precise bends (E-plane and H-plane), miters, and twists. Each component is designed to change the direction of the waveguide path with minimal impact on signal performance, preserving low VSWR and insertion loss.

Signal Control and Distribution: Directional Couplers, Dividers/Combiners & Tees

Managing the signal path requires specialized components. We create custom directional couplers for signal sampling, as well as power dividers, combiners, and magic tees for splitting or combining signals within the assembly.

Specialized Components for Diverse RF Functions

Our capabilities extend to a host of other specialized waveguide components, including filters, attenuators, terminations, and pressure windows, all of which can be integrated into a complete, custom-engineered assembly.

Applications Demanding Uncompromising Precision

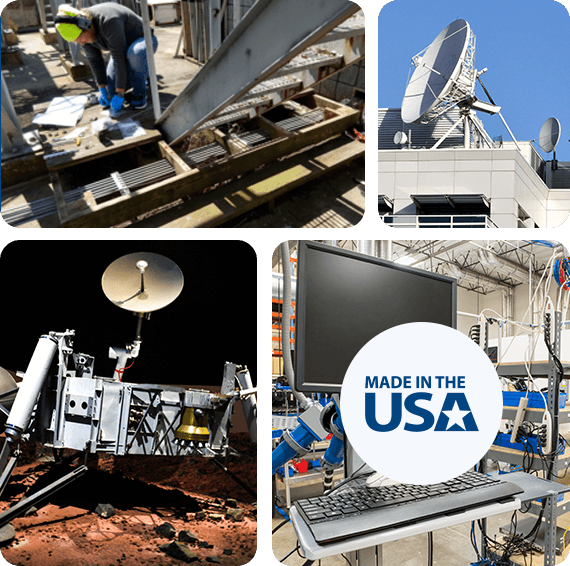

Our custom waveguide assemblies provide the critical performance and reliability required in the world’s most demanding sectors.

Defense, Military, and Surveillance Systems: Reliability in Critical Environments

In radar, electronic warfare, and secure communication systems, reliability is non-negotiable. Our ruggedized waveguide assemblies are built to withstand the harshest operational conditions while delivering consistent, superior performance.

Space and Satellite Communications: Earth Stations, Teleports, VSAT Systems, and Space Flight Components

From ground-based earth stations to space-flight hardware, our custom waveguide products provide the high-power handling and low-loss transmission essential for clear, reliable satellite communication links.

Advanced RF Communication Networks

Modern communication infrastructure relies on high-fidelity signal transmission. Our waveguide assemblies form the backbone of advanced networks, ensuring maximum data throughput and system efficiency.

Test & Measurement and Scientific Research (e.g., demanding WR-03, WR-12 Waveguide performance)

Scientific discovery and precision testing depend on immaculate signal purity. We build ultra-precise waveguide components, including those for extremely high frequencies like WR-12 or WR-03, for particle accelerators, radio astronomy, and advanced research labs.

Industrial and Medical High-Power Applications

In industrial heating, material processing, and medical accelerators, our custom waveguide assemblies are engineered to safely and efficiently handle extremely high levels of RF power, ensuring both performance and operational safety.