Rectangular Waveguide Design & Manufacturing Services

The Unseen Criticality of Waveguides in Space

Waveguides are the essential arteries of modern space systems, guiding high-frequency electromagnetic waves with minimal loss. These crucial components are fundamental to the operation of satellite communication links, Earth observation radars, and deep space telemetry systems, acting as the primary transmission lines between the antenna and electronic parts.

Why Standard Solutions Fall Short for Space Applications

Off-the-shelf waveguide components are not engineered for the vacuum, extreme temperature fluctuations, and intense radiation of space. Standard parts risk material outgassing, structural failure, and signal degradation, posing an unacceptable threat to mission objectives. Space machines demand solutions designed from the ground up for survivability and reliability.

Our Expertise: Custom Design and Manufacturing for the Cosmos

We provide a specialized service focused exclusively on custom rectangular waveguides for space. Our expertise bridges the gap between theoretical RF design and flight-qualified manufacturing, producing bespoke components and assemblies that meet the stringent performance and environmental requirements of any mission.

The Unique Demands of Space Machines on Waveguide Design

Harsh Environments: Vacuum, Extreme Temperatures, and Radiation

Our waveguides are designed to withstand the brutal conditions of space. This includes thermal cycling from -150°C to +150°C, the hard vacuum that can cause material outgassing, and radiation that can degrade material properties. Material selection and structural engineering are optimized for this environment.

Mission-Critical Reliability: Zero Tolerance for Failure

In space, there are no second chances. Every rectangular waveguide we produce is built for absolute dependability. Our design philosophy and manufacturing processes are governed by a zero-failure tolerance, ensuring that our parts perform reliably throughout the entire mission duration.

Size, Weight, and Power (SWaP) Constraints: Optimizing for Payload

Every gram and cubic centimeter counts on a spacecraft. We specialize in optimizing waveguide designs to minimize mass and volume without compromising performance. This meticulous approach to SWaP helps maximize payload capacity and reduce launch costs.

Long-Term Operational Lifespan in the Void

Space machines are expected to operate for years or even decades without maintenance. Our custom waveguides are engineered for exceptional longevity, using materials and manufacturing techniques that prevent degradation and ensure stable, long-term performance.

Rectangular Waveguide Fundamentals: Tailored for Space Performance

Principles of Electromagnetic Wave Propagation in Rectangular Waveguides

A rectangular waveguide confines and directs electromagnetic waves, typically in the microwave spectrum. The signal propagates in specific patterns known as modes, with the Transverse Electric (TE) mode being the most common. We engineer the geometry to ensure the dominant TE mode propagates efficiently for clear signal transmission.

Cutoff Frequency and Operating Frequency Range

Every waveguide has a cutoff frequency below which signals will not propagate. We precisely design the waveguide sizes and dimensions to establish an optimal operating frequency range, ensuring your system operates efficiently and without interference from unwanted modes.

Attenuation, Signal Integrity, and Power Handling

For space applications, minimizing signal loss (attenuation) is critical. Our designs focus on ultra-smooth internal surfaces and precise geometries to preserve signal integrity. We also engineer our components to handle the high power levels required by modern radars and communication systems.

Voltage Standing Wave Ratio (VSWR) and Impedance Matching

Mismatches in the transmission line cause signal reflections, measured by VSWR. A high VSWR reduces efficiency and can damage components. Our custom waveguide assemblies are meticulously designed for excellent impedance matching, resulting in a low VSWR and maximum power transfer.

Custom Design Services: Engineering Precision for Space Environments

Advanced Material Selection for Space-Grade Waveguides

We utilize a range of space-qualified materials, including lightweight aluminum alloys, oxygen-free copper for high conductivity, and specialized alloys like Invar for superior thermal stability. Material choice is tailored to the specific thermal, structural, and RF requirements of your space machine.

Precision Engineering of Waveguide Sizes and Geometries

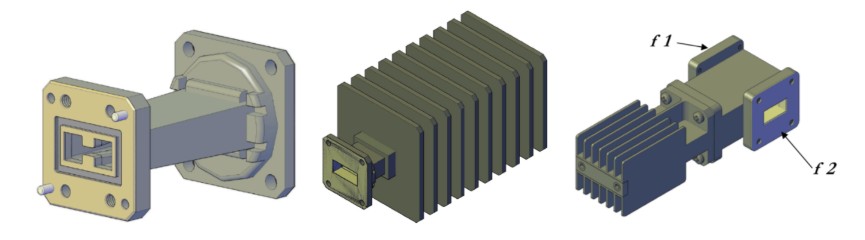

We design and manufacture both standard and entirely custom waveguide sizes. Our engineering team precisely controls internal dimensions, corner radii, and flange interfaces to achieve targeted electrical performance and ensure perfect integration with other system components.

Complex Waveguide Assemblies and RF Components

Our capabilities extend beyond simple waveguide sections. We design and build complex, integrated waveguide assemblies that incorporate bends, twists, couplers, filters, and transitions. These assemblies are delivered as a single, verified unit, simplifying system integration.

Simulation and Design Optimization with Advanced Tools (e.g., HFSS)

Using industry-leading software like Ansys HFSS, we simulate and optimize every design before manufacturing. This allows us to predict performance, refine geometries, and ensure the final product will meet all mission specifications, reducing development time and risk.

Manufacturing Excellence: Producing Flight-Qualified Space Waveguides

Our State-of-the-Art Manufacturing Facility for Aerospace Components

Our AS9100D-certified facility is equipped with advanced CNC machining, precision forming, and specialized plating capabilities dedicated to producing aerospace and defense components. Every step of the manufacturing process is tightly controlled to ensure exceptional quality.

Stringent Quality Assurance and Industry Certifications

Quality is embedded in our process. We adhere to the highest industry standards for aerospace manufacturing. Rigorous inspection, material traceability, and process validation ensure that every waveguide delivered is flight-ready and fully compliant.

Scalable Production from Prototyping to High-Volume Runs

We support missions at every scale, from initial engineering prototypes for new satellite concepts to full-scale production runs for constellations. Our manufacturing process is flexible and scalable to meet your project’s unique volume and timeline requirements.

Integrated Assembly and Testing of Custom Waveguide Setups

We provide fully assembled and tested waveguide solutions. Our team integrates all necessary parts and performs comprehensive RF testing to verify key parameters like VSWR, insertion loss, and isolation, delivering a flight-qualified assembly ready for integration.

Applications in Modern Space Missions: Where Our Waveguides Operate

Satellite Communication and High-Throughput Data Links

Our rectangular waveguides are critical components in GEO, MEO, and LEO satellite communication payloads, enabling the high-throughput data links that power global connectivity.

Radar Systems and Earth Observation Satellites

For synthetic aperture radar (SAR) and other remote sensing satellites, our high-power waveguides form the backbone of the antenna feed networks, enabling precise Earth observation and imaging.

Scientific Payloads and Deep Space Probes

From radio astronomy instruments to interplanetary communication systems, our reliable waveguides ensure that invaluable scientific data is successfully transmitted from the farthest reaches of our solar system.

Other Aerospace and Defense Applications

Beyond space, our custom waveguide solutions are used in a variety of high-performance aerospace and defense platforms where reliability and performance are non-negotiable.