Waveguide Adapters Design & Manufacturing Services

Precision-engineered adapters for mission-critical RF links.

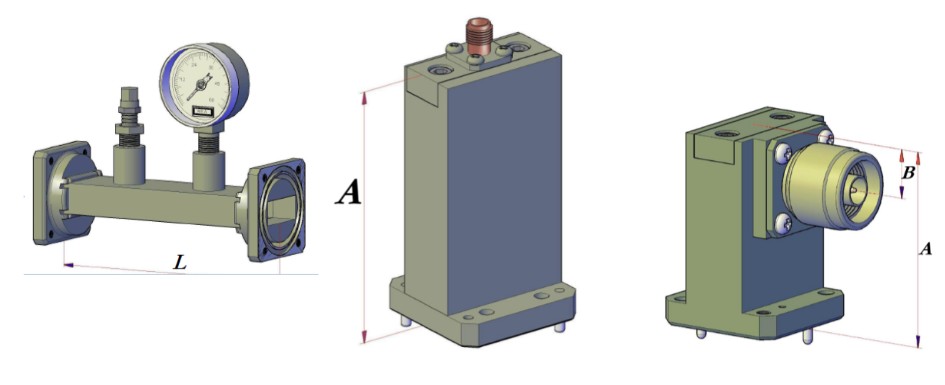

Space Machine designs and manufactures custom waveguide adapters that deliver low-loss, high-integrity transitions between sizes, standards, and media—rectangular-to-rectangular, double-ridged, and coax-to-waveguide—for aerospace, defense, and satellite communications.

Why Waveguide Adapters Matter in Space

Waveguide adapters are the link that makes heterogeneous RF systems work. In flight environments, they must transition power cleanly without reflections, added loss, or mechanical risk—all while surviving vacuum, thermal cycling, vibration, and radiation. Off-the-shelf parts rarely meet those constraints. Space Machine builds adapters from the ground up for survivability, reliability, and repeatable performance.

Built for Space Environments

- Vacuum readiness: low-outgassing materials, space-grade platings, controlled finishes.

- Thermal stability: geometry and joints engineered for extreme temperature swings.

- Radiation awareness: material and plating choices selected to limit degradation.

- SWaP optimization: mass and envelope minimized without compromising RF performance.

Engineering & Design Capabilities

- Adapter Types: rectangular-to-rectangular, double-ridged transitions, coax-to-waveguide, flange standard conversions, pressure-tight bulkhead adapters, test adapters.

- RF Performance: low VSWR/return loss targets, tight insertion-loss budgets, high-power handling, mode control.

- Simulation-driven design: full-wave EM modeling (e.g., HFSS) to validate and optimize before build.

- Mechanical integration: custom flanges, hole patterns, dowel/anti-rotation features, thermal straps, alignment keys.

Materials & Finishes

- Space-qualified alloys: aluminum, OFHC copper, specialty stability alloys.

- Surface treatments: chem film, silver or gold plating, and proprietary finishes for conductivity, corrosion control, and emissivity management.

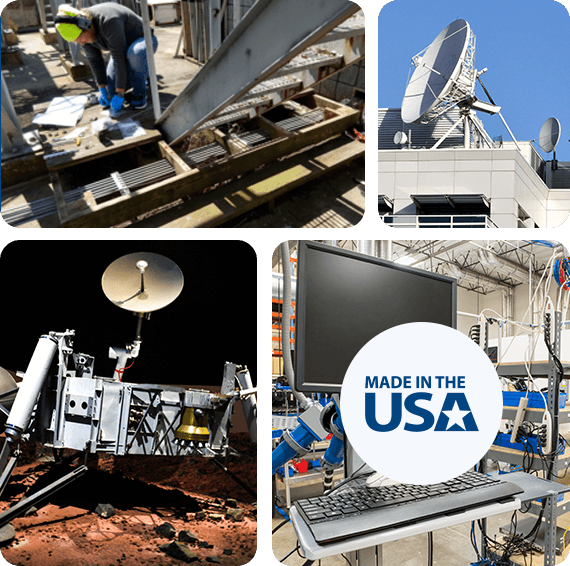

Manufacturing & Quality

- AS9100-driven workflows: high-tolerance CNC machining, precision joining, controlled plating.

- Flight-qualification mindset: material traceability, process validation, traveler documentation.

- End-to-end testing: vector network analysis for VSWR, insertion loss, return loss; pressure and leak checks where specified; environmental screening per program needs.

- Scalable builds: from rapid engineering prototypes to constellation-scale production.

Waveguide Adapter Applications

- Satellite payloads: transceiver front-ends, filter/coupler chains, antenna feed networks.

- Earth observation & radar: high-power transitions in SAR and radiometry instruments.

- Deep-space & scientific payloads: ultra-stable, low-loss links for long-duration missions.

- Defense platforms: ruggedized adapters for airborne and naval RF systems.